Standard Pallet Size Dimensions: The Ultimate Guide for Logistics Professionals

In the world of logistics, efficiency is everything. One of the often-overlooked components that can significantly impact shipping costs, space optimization, and operational flow is the standard pallet size. From freight planning to warehouse stacking, understanding pallet dimensions and specifications is essential for logistics professionals.

This comprehensive guide covers standard pallet dimensions, regional variations, material types, use cases, and best practices to help you streamline your supply chain.

Why Understanding Pallet Dimensions Matters

Pallets are the foundation of freight logistics, and understanding standard pallet dimensions ensures smoother and more cost-effective operations.

- Freight Cost Accuracy: Most shipping quotes—especially in LTL freight—depend on the total size and weight of your freight including the pallet. Inaccurate dimensions can lead to reclassification and unexpected charges.

- Container & Trailer Optimization: Whether you’re loading a 20-foot ocean container or a domestic trailer, knowing the exact pallet size helps maximize space and reduce empty gaps that cost money.

- Equipment Compatibility: Pallets must fit forklifts, pallet jacks, conveyor belts, and racking systems. A mismatch leads to delays or unsafe handling. That’s why using standard pallet specs minimizes risks and operational slowdowns.

- Global Consistency: When shipping internationally, different countries follow different pallet standards. Awareness of these avoids customs issues or the need to repack freight at borders.

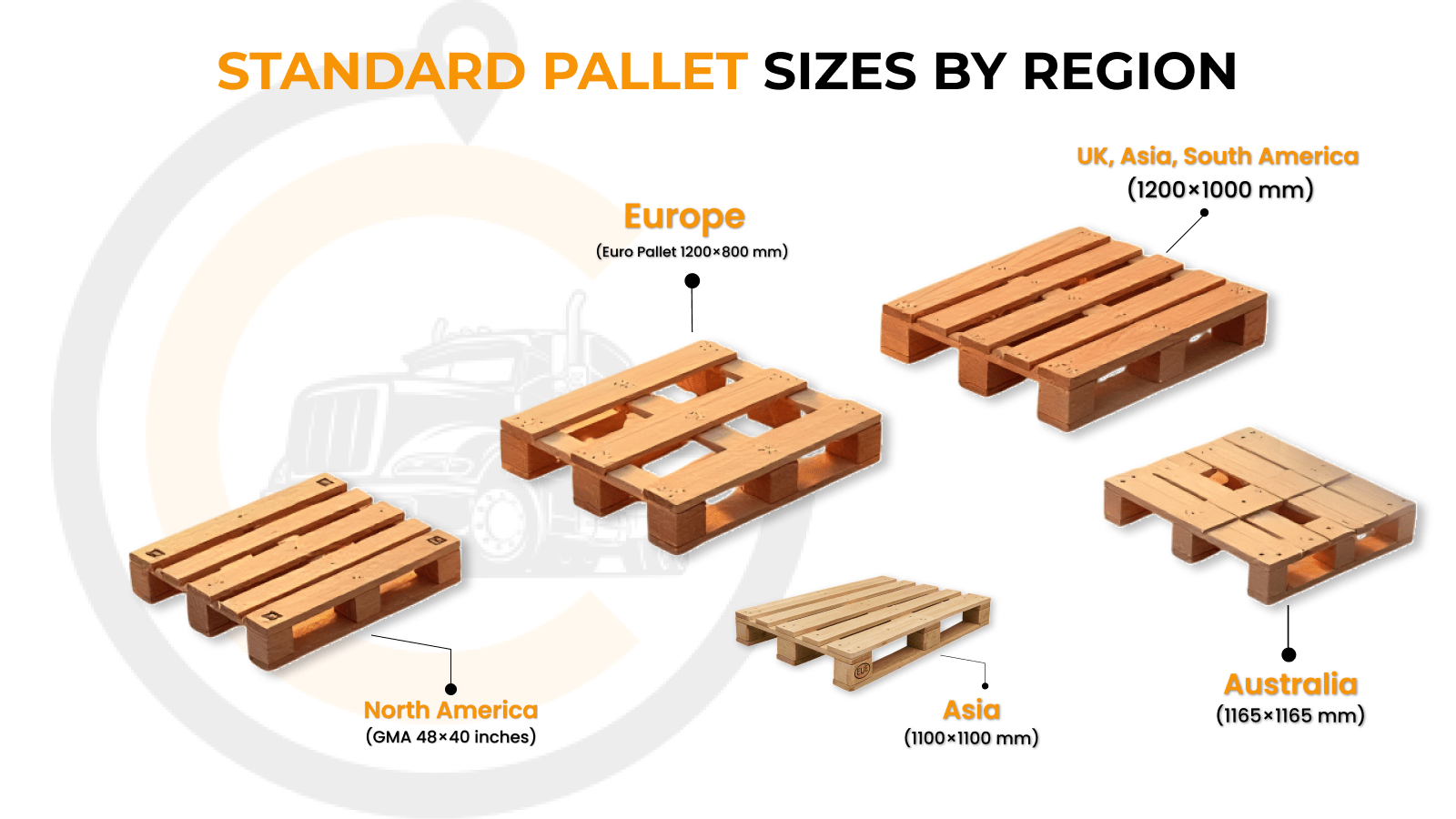

Standard Pallet Sizes by Region

Let’s break down the typical pallet sizes used in different parts of the world and what makes them important:

- North America (GMA 48×40 inches): The most common pallet in the U.S. and Canada, used by nearly 30% of the industry. It fits well in standard trailers and warehouse racking.

- Europe (Euro Pallet 1200×800 mm): Adopted across EU countries and compliant with ISO standards. It’s designed to maximize space in European trucks and warehouses.

- UK, Asia, South America (1200×1000 mm): Larger surface area makes this ideal for heavier industrial loads.

- Asia (1100×1100 mm): A square pallet often used in the food and beverage sector, especially in Japan, Korea, and China.

- Australia (1165×1165 mm): Built for local storage systems, this size is optimized for Australian rail containers.

- Half and Quarter Pallets (800×600 mm, 600×400 mm): Designed for smaller shipments or retail display, common in Europe and e-commerce packaging.

Understanding these dimensions helps you choose the right pallet for international shipping and domestic distribution alike.

Common Pallet Measurements Explained

Every logistics professional should understand the key components of pallet sizing:

- Length and Width: These form the pallet’s footprint. For example, the standard U.S. pallet is 48 inches long and 40 inches wide.

- Height: Typically between 5.5 to 6.5 inches, depending on material and design. Height is crucial for calculating total freight volume.

- Deckboard Configuration: Top deck boards can be solid or slatted, affecting load stability. Bottom deck configuration impacts forklift entry.

- Four-way vs Two-way Entry: Four-way pallets allow forklifts to access from all sides, making them more versatile and easier to maneuver in tight warehouse spaces.

Knowing these pallet measurements ensures accurate load planning, billing, and safer material handling.

Materials Used in Pallets

The material of your pallet can influence its strength, cost, and suitability for certain industries:

1. Wooden Pallets

- Pros: Cost-effective, widely available, customizable.

- Cons: May splinter or degrade over time. Requires heat treatment for export (ISPM 15 compliance).

- Use Case: Perfect for domestic shipping and short-term use.

2. Plastic Pallets

- Pros: Durable, hygienic, weather-resistant, and ideal for reuse.

- Cons: Higher initial cost.

- Use Case: Best for pharmaceuticals, food, and international shipments where cleanliness and reusability matter.

3. Metal Pallets

- Pros: Extremely strong and durable.

- Cons: Heavy and expensive.

- Use Case: Ideal for automotive, aerospace, or industrial applications with heavy loads.

Selecting the right pallet material directly affects handling costs and operational efficiency.

Pallet Load Capacities

Not all pallets are built the same. Here’s how load capacity varies:

- Static Load: The weight a pallet can support while at rest on a solid surface.

- Dynamic Load: The weight it can handle while being moved (e.g., by forklift).

- Racking Load: The weight a pallet can hold when stored on a warehouse rack.

For example:

- A standard wood pallet can support ~2,800 lbs of dynamic load.

- High-strength plastic pallets can support up to 5,000 lbs and even more for static loads.

Knowing your load type helps you select the right pallet to avoid collapse or injury during transit or storage.

Impact of Pallet Dimensions on Freight & Warehousing

1. Freight Pricing

Most freight carriers charge by dimensional weight, which includes your product plus the pallet. Overestimating or underestimating size leads to costly adjustments.

2. Warehouse Efficiency

Standard sizes allow you to:

- Stack pallets safely

- Align with standard racking widths

- Reduce wasted floor space

- Streamline inventory management

3. International Container Loading

Using standard pallets ensures you can fit maximum units inside containers—reducing your per-unit shipping cost. For example:

- Euro-pallets fit 11 per 20ft container

- GMA pallets fit 10–11 in a 20ft and 20–21 in a 40ft container

That’s why pallet size standardization plays a key role in logistics design.

Best Practices for Logistics Professionals

Here are key guidelines to follow for efficient pallet use:

- Measure & Document: Always include the pallet when calculating shipment dimensions.

- Label Pallets Clearly: Include weight, dimensions, destination, and handling symbols.

- Use Standard Sizes: Avoid custom sizes unless absolutely necessary—they slow down processing.

- Inspect Regularly: Damaged pallets can collapse during transport or storage.

- Plan for Stack Height: Especially for warehouse storage and shipping in closed containers.

Following these pallet best practices reduces delays, improves safety, and saves money.

Frequently Asked Questions

Q: What is the standard pallet size in the USA?

A: The standard U.S. pallet size is 48 x 40 inches, commonly known as the GMA pallet.

Q: What is the height of a standard pallet?

A: A typical pallet is about 6 inches tall, but this can vary slightly based on material.

Q: What is the standard Euro pallet size?

A: The Euro pallet measures 1200 x 800 mm and is ISO compliant for use across the EU.

Q: Can I use plastic pallets for export?

A: Yes. Plastic pallets don’t require heat treatment and are ideal for international shipping.

Q: Are there smaller pallet sizes?

A: Yes. Half-pallets (800×600 mm) and quarter-pallets (600×400 mm) are commonly used for retail, e-commerce, and compact shipping.

Mastering standard pallet size and dimensions is more than just a technical requirement—it’s a strategic advantage. Whether you’re managing a warehouse, coordinating freight, or planning international shipments, knowing the right pallet size standard helps reduce costs, improve safety, and enhance efficiency.

Take the time to understand the sizes, materials, and load capacities relevant to your region and industry. It’s a small step with a massive impact on your logistics performance.

Comments are closed