Common Shipping Terms Every Business Should Know

If you’ve ever felt lost in a sea of shipping abbreviations, freight terms, and logistics jargon—you’re not alone. Shipping terminology can feel overwhelming, but knowing the right terms can make a huge difference in how effectively your business moves products.

For U.S. businesses that rely on logistics, understanding shipping terms isn’t just about communication—it’s about cutting costs, negotiating smarter, and avoiding delays. Many companies also benefit from outsourcing smarter supply chain solutions. Whether you’re new to logistics or managing complex supply chains, this glossary will help you decode the most common shipping terms and put them into practice.

What Do Shipping Terms Mean?

Shipping terms (also called freight terms or cargo shipping terms) define responsibilities between buyers, sellers, carriers, and customers during transportation. They clarify:

- Who pays for shipping costs

- When risk transfers from seller to buyer

- Which documents are required

- How goods move across borders

By mastering shipping definitions, businesses can streamline operations, reduce errors, and strengthen relationships with suppliers and logistics partners. If you’re new to logistics, you might also find this list of essential logistics terms helpful for building a solid foundation.

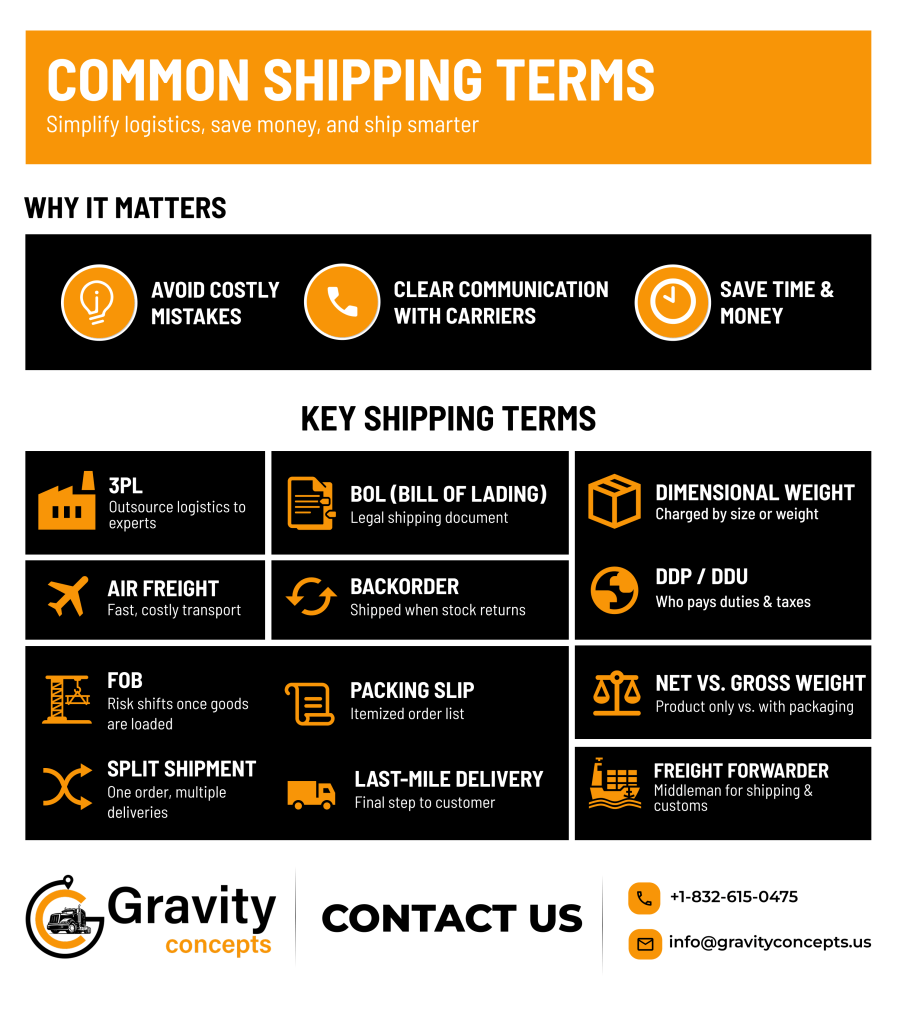

Key Shipping Terms and Definitions

Below is a breakdown of essential shipping terminology that every business should know.

1. 3PL (Third-Party Logistics)

A 3PL provider handles logistics services such as warehousing, order fulfillment, and transportation on behalf of businesses. Outsourcing to a 3PL can reduce costs and free up internal resources. To learn how this works step by step, explore our beginner’s guide to 3PL.

Why it matters: Helps growing businesses scale without investing in their own fleet or warehouse.

2. Bill of Lading (BOL)

A legal document issued by a carrier acknowledging receipt of cargo for shipment. It acts as both a contract and a receipt.

Why it matters: Required for international and domestic freight shipments to prove ownership and establish liability.

3. Air Freight

Refers to cargo transported by aircraft. It’s the fastest mode but also the most expensive.

Best for: High-value, time-sensitive shipments such as electronics or medical supplies.

4. Backorder

An order placed for an item that is currently out of stock and will be shipped once inventory is replenished.

Why it matters: Helps businesses manage customer expectations and maintain sales even when stock is low.

5. Dimensional Weight (Volumetric Weight)

A pricing method based on a package’s size rather than its actual weight. Carriers charge whichever is greater—actual weight or dimensional weight.

Tip: Reducing packaging size can cut freight costs. Businesses should also be aware of standard pallet size dimensions when preparing larger freight shipments.

6. DDP (Delivered Duty Paid)

The seller covers all costs and risks until goods are delivered to the buyer, including duties, tariffs, and customs.

Why it matters: Attractive for international buyers since they don’t face hidden costs.

7. DDU (Delivered Duty Unpaid)

Unlike DDP, the buyer is responsible for customs duties and taxes upon arrival.

Why it matters: Lowers seller costs but can create friction if buyers aren’t prepared for additional fees.

8. Ex-Works (EXW)

The seller makes goods available at their premises, but the buyer assumes all responsibility for transport, insurance, and customs clearance.

Best for: Experienced importers who can arrange logistics independently.

9. Free Carrier (FCA)

The seller delivers goods to a carrier or location chosen by the buyer, handling export duties but not full transportation.

10. Free on Board (FOB)

The seller is responsible until goods are loaded on the ship. After that, the buyer assumes risk and costs.

Why it matters: Common in ocean freight agreements.

11. Freight Forwarder

An intermediary who arranges shipping, negotiates rates, and manages customs paperwork.

Benefit: Simplifies complex international logistics for businesses of all sizes.

12. Last-Mile Delivery

The final step of shipping, from the local hub to the customer’s doorstep.

Challenge: It’s often the most expensive and logistically difficult part of the supply chain.

13. Net Weight vs. Gross Weight

- Net Weight: Weight of the product only

- Gross Weight: Product plus packaging and container

Why it matters: Affects freight charges and customs declarations.

14. Packing Slip

A document listing items included in a shipment, often used by warehouses to confirm order accuracy.

15. Split Shipment

When a customer order is shipped in multiple deliveries due to stock availability or different warehouse locations.

Impact: Increases costs but can improve customer satisfaction.

16. Shipping Zones

Carriers divide regions into zones (1–8 in the U.S.). Costs rise the farther the destination is from the origin. For businesses moving containers from ports to warehouses, our drayage trucking services help reduce costs tied to shipping zones.

Tip: Distributing inventory across multiple warehouses reduces zone-based costs.

17. White-Glove Delivery

A premium delivery service that includes setup, installation, or placement in a customer’s home or business.

Example: Furniture and heavy equipment delivery.

Shipping Abbreviations You Should Know

- ETA (Estimated Time of Arrival): Expected delivery date.

- ETD (Estimated Time of Departure): When a shipment leaves the origin point.

- FCL (Full Container Load): Entire container reserved for one shipper.

- LCL (Less than Container Load): Shared container space with other shippers.

- SOC (Shipper-Owned Container): Container owned by the shipper rather than the carrier.

How Understanding Freight Terminology Helps Businesses

- Improves Negotiations: Clear terms prevent miscommunication with suppliers and carriers.

- Reduces Costs: Knowing about dimensional weight or zones helps cut unnecessary expenses.

- Speeds Up Processes: Accurate documents (BOL, packing slips) prevent customs delays.

- Enhances Customer Experience: Better last-mile delivery planning leads to faster, more reliable service.

FAQs About Shipping Terms

Q1. What do shipping terms mean in logistics?

They define responsibilities, costs, and risks between buyers, sellers, and carriers during transportation.

Q2. What’s the difference between freight terms and shipping terms?

They’re often used interchangeably. Freight terms usually refer to large-scale cargo shipments, while shipping terms can include both parcel and freight logistics.

Q3. Why is a Bill of Lading important?

It acts as both a receipt and a contract, ensuring accountability for goods in transit.

Q4. How do shipping zones affect costs?

The farther the destination (higher zone), the more you pay. Businesses often use multiple warehouses to reduce costs.

Q5. Should small businesses learn shipping terminology?

Yes—clear understanding helps avoid costly mistakes, improves carrier negotiations, and boosts efficiency.

Conclusion: Speak the Language of Shipping

Shipping may be complex, but learning the right terminology makes it manageable. From cargo shipping terms to freight abbreviations, every definition you master adds clarity to your logistics strategy. For U.S. businesses, this knowledge translates into lower costs, faster deliveries, and better customer satisfaction.

By keeping this glossary handy, you’ll not only navigate logistics with confidence but also stay ahead in today’s fast-moving supply chain world.

Comments are closed